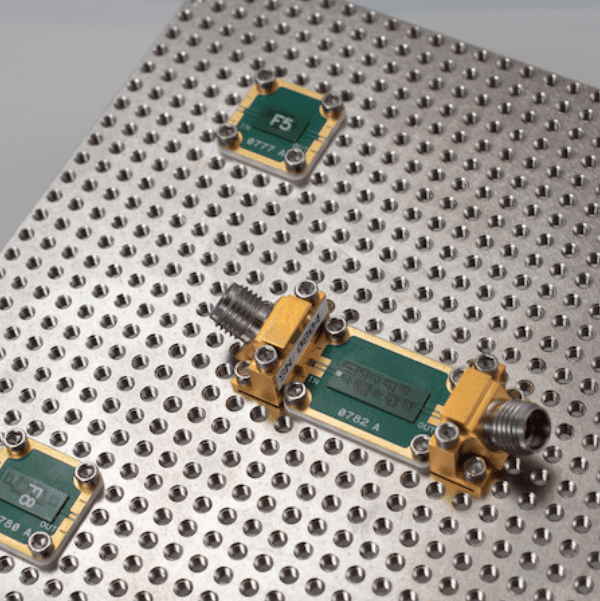

Choosing the right filter is an art balancing size, cost, performance, and fabrication time. There are many approaches available in the X-Microwave system for both off-the-shelf and custom filter solutions.

Off-the-shelf Filter Library

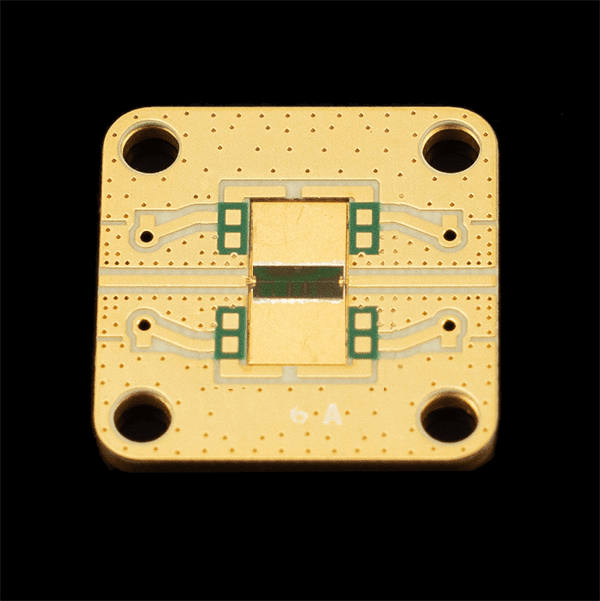

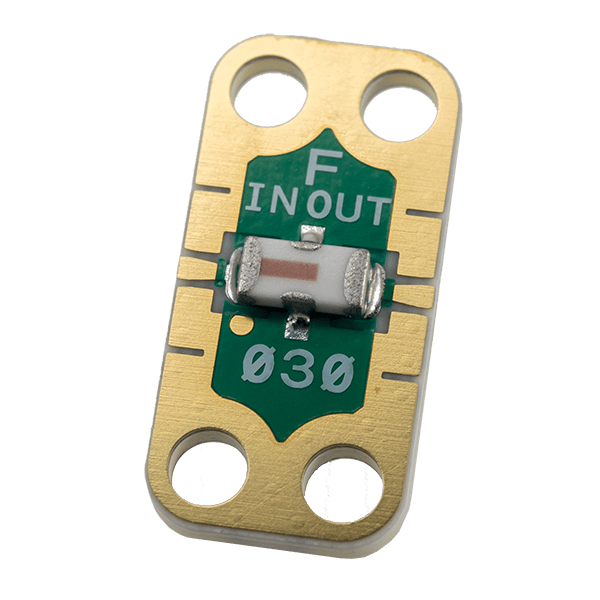

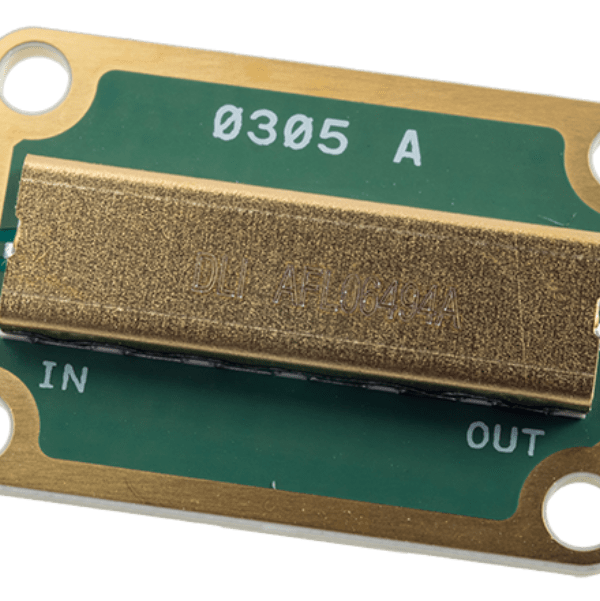

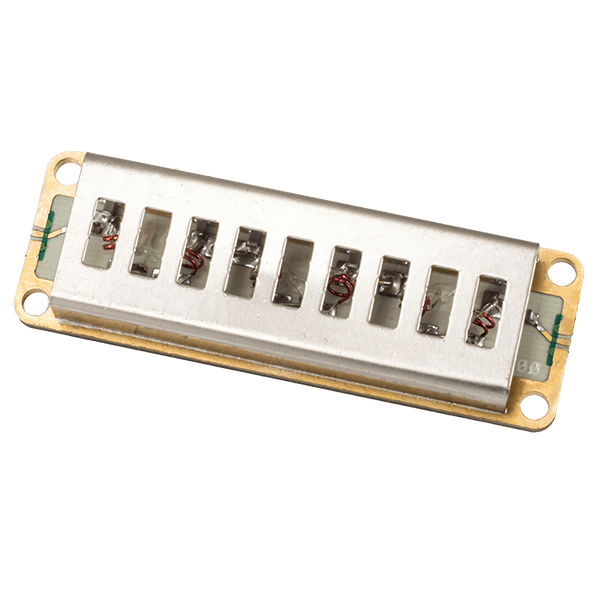

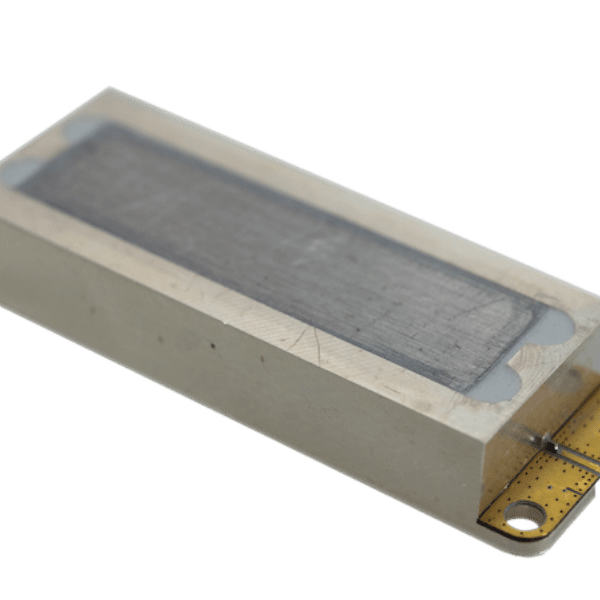

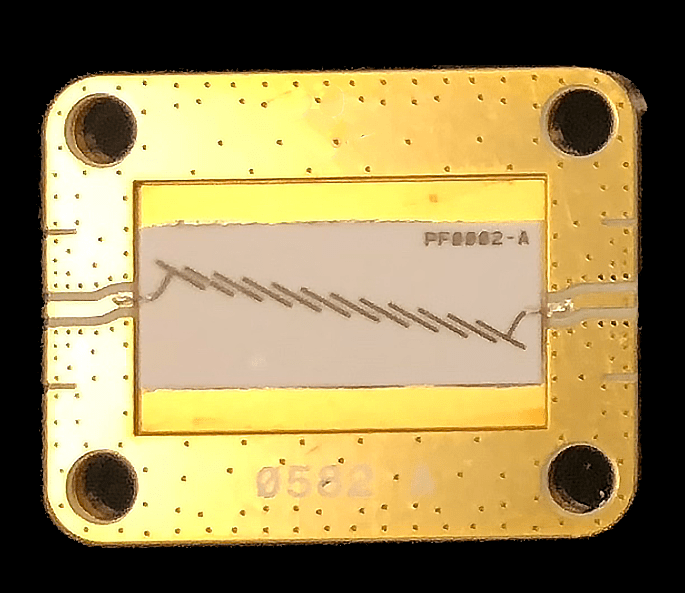

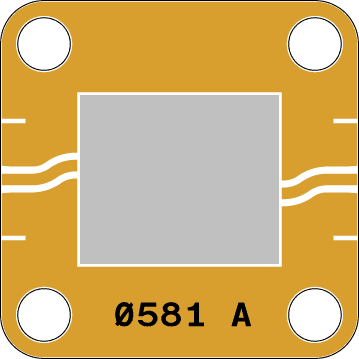

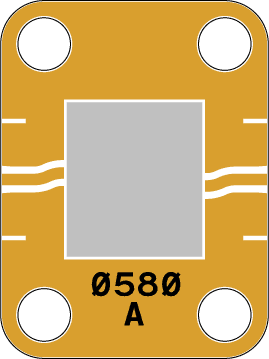

Hundreds of read-made filters are available using a wide range of technologies including Lumped element and LTCC filters from MiniCircuits, MLO Filters from AVX, thin film ceramic from DLI/Knowles, tunable filters from Analog Devices and Atlanta Microwave, and MMIC wire bondable filters from Marki Microwave (to name a few). They offer a relatively quick, convenient, and low cost way to design a filter into your system.